Comparison |  |  |  |

|---|---|---|---|

| www.MachinerySliders.com | Multi directional Slider | Single directional Slider | Dollies and Skates |

| Extremely safe and user friendly | |||

| Lightweight, less than 1.5 lbs. | |||

| 1" or lower reducing tip-over | |||

| Ideal for unstable loads. | |||

| Easy on/off, in/out of trailers & containers | |||

| Low Cost: a fraction of the cost | |||

| Works on clean or dirty floors | |||

| Works on wood, tile, & carpet floors | |||

| Easily slide over dock plates & damaged concrete | |||

| Usable in less capacity on asphalt | |||

| Single directional travel. | |||

| Risk of muscle strain: heavy to lift | |||

| 360° directional travel | |||

| Low overhead clearance - 3/8" to 1" tall | |||

| Use multiple to increase capacity (~10 ton each) | |||

| Greater risk of tip-over | |||

| High Risk |

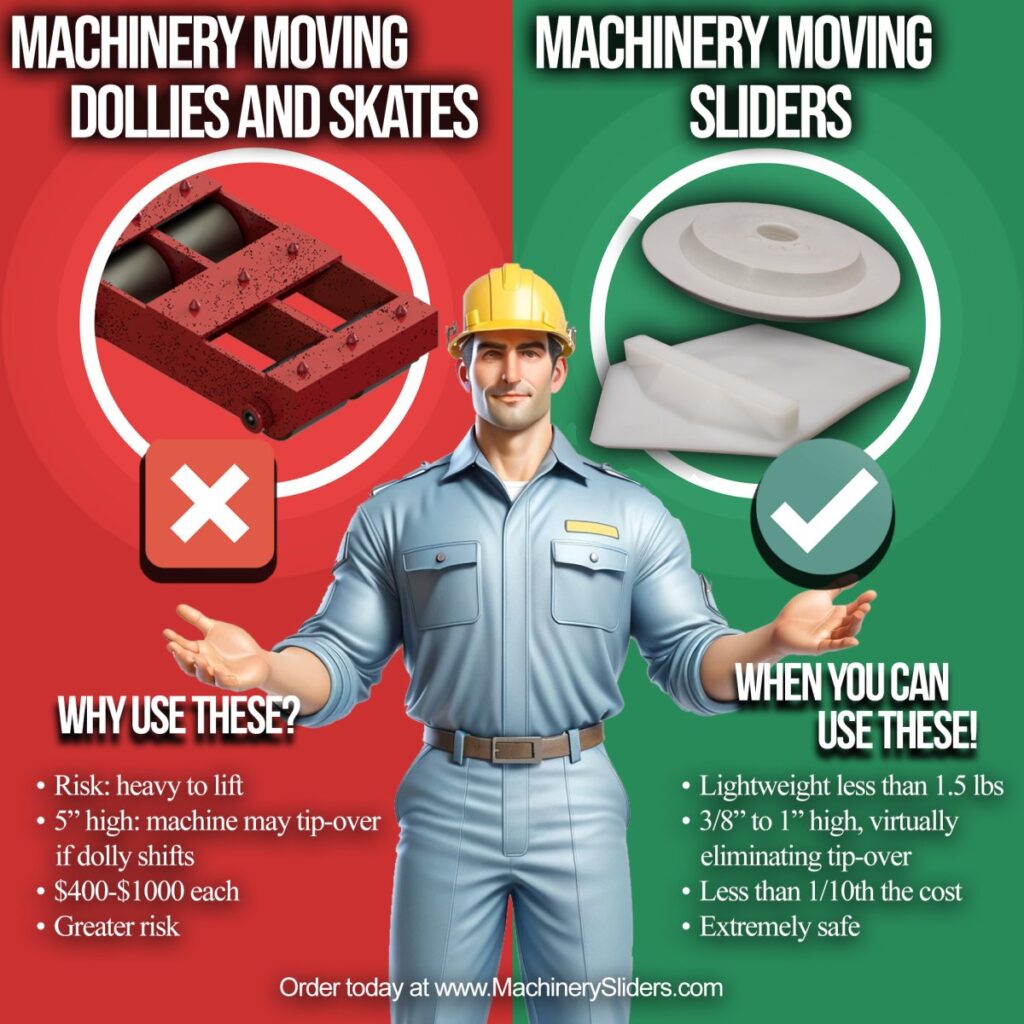

It is a fact, that once a rigger or machinery mover uses Machinery Sliders, they do not go back to traditional dollies or skates unless the specific application warrants it.

The bottom-line is: Machinery Sliders save time, reduce the risk of machinery damage and human accidents, and makes the machinery or equipment move, easier.

The three (3) most important things that Machinery Sliders do for the machinery mover and rigger are: Increases the overhead clearance by reducing the height of the machine being moved; greatly lowers the center of gravity of tall heavy machinery virtually eliminating tip-over; and saves time moving the machine because they are light weight, easy and safe to use.

Machinery Sliders have been reducing the high risk of machinery moving and rigging since 2014.

In the image to the right there are three styles of Machinery Sliders. The pointed-tipped Single-Directional in which the machine base will sit behind the top bumper while the forklift either pulls or pushes the machine in the direction of the point. The Multi-Directional type with a 1" hole will sit under a leveling pad frame and pinned in place by a 1" bolt or pin that will fit. And the Multi-Directional with a 4" hole is made for machinery with leveling pads to fit right in without removing the leveling pad.